The Role of Slitting Lines in Precision Steel Processing

Steel processing is a cornerstone of modern manufacturing, with slitting lines playing an essential role in transforming raw material into usable components. These lines are pivotal in cutting large coils of steel into narrower strips, tailored to meet the specific requirements of various industries. This article explores the intricacies of slitting lines, their significance, the technology driving them, and their applications across different sectors

Understanding Slitting Lines

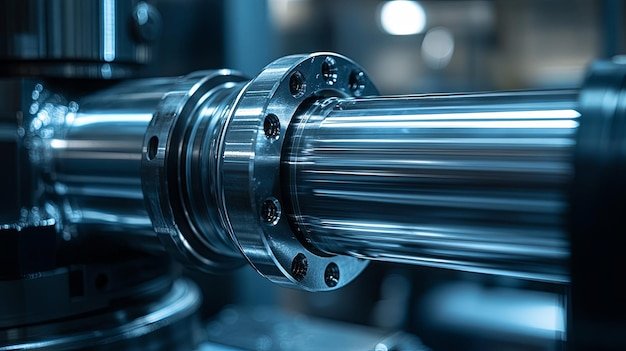

Slitting lines are specialized machines designed to cut wide rolls of steel into narrower strips with precise dimensions. The process begins with an uncoiling mechanism that feeds the steel coil into the slitting line. As the coil moves through the machine, it encounters sharp rotary blades that slice it into the desired widths. This operation is not only efficient but also ensures a high level of precision, which is crucial for many applications.

Components of a Slitting Line

- Uncoiler: This component unwinds the large steel coil, preparing it for the slitting process. It must be properly aligned to ensure smooth feeding into the machine.

- Slitter: The heart of the operation, this part houses the rotary blades that perform the actual cutting. The alignment and sharpness of the blades are vital for achieving clean cuts.

- Recoiler: After the steel has been slit, this component rewinds the narrower strips into smaller coils, ready for shipping or further processing.

The Process Flow

The slitting process involves several steps:

- Loading: The steel coil is placed onto the uncoiler.

- Feeding: The coil is fed into the slitter under controlled tension.

- Cutting: Rotary blades slice the coil into strips of specified widths.

- Rewinding: The recoiler gathers the slit strips into manageable coils.

Each step must be executed with precision to ensure the quality of the final product.

Importance of Precision in Slitting

Precision is a fundamental aspect of slitting lines. The exactness of the cuts directly influences the usability of the steel strips in various applications. Industries such as automotive, construction, and appliance manufacturing rely heavily on the uniformity of these strips.

Benefits of Precision

- Reduced Waste: Accurate cuts minimize scrap material, leading to cost savings and reduced environmental impact.

- Enhanced Quality: High precision ensures that the dimensions of the strips meet the specifications required for downstream processes.

- Improved Efficiency: When the slitting process is precise, it allows for quicker production times and less downtime for adjustments.

Tolerance Levels

Modern slitting lines can achieve tolerances as tight as ±0.002 inches. This level of precision is essential for applications where exact dimensions are critical, such as in parts that must fit together seamlessly.

Innovations in Slitting Technology

The steel processing industry has seen remarkable advancements in slitting technology over the years. These innovations have significantly improved efficiency, accuracy, and overall productivity.

Automation and Control Systems

- Automated Operations: Many slitting lines now feature automated controls that streamline the entire process. This reduces the likelihood of human error and increases production rates.

- Real-Time Monitoring: Advanced systems equipped with sensors and cameras allow for real-time monitoring of the cutting process, ensuring that any deviations from the specified dimensions are quickly identified and corrected.

Blade Technology

- Material Improvements: Innovations in blade materials have enhanced their durability, reducing the frequency of replacements and maintenance.

- Design Enhancements: The design of slitting blades has evolved to improve cutting efficiency and extend their lifespan, contributing to lower operational costs.

Applications Across Industries

The versatility of slitting lines makes them invaluable across a range of sectors. From automotive to construction, the precise strips produced by these machines find numerous applications.

Automotive Industry

In the automotive sector, steel strips are crucial for manufacturing components such as:

- Brackets: Used for mounting various parts within vehicles.

- Chassis Components: Essential for vehicle structure and safety.

- Reinforcements: Critical for enhancing the strength of safety features like seatbelts.

Construction Sector

Steel strips produced through slitting are widely used in construction for:

- Roofing Materials: Providing durability and strength to structures.

- Structural Beams: Essential for supporting buildings and bridges.

- Panels: Used in a variety of applications, from walls to flooring.

Consumer Goods

Everyday items such as kitchen appliances and electronic devices often contain components made from slit steel strips. These applications showcase the adaptability and necessity of slitting lines in modern manufacturing.

Cost Efficiency and Waste Reduction

One of the standout advantages of using slitting lines is their ability to reduce costs and waste. The efficiency of the slitting process translates to significant savings for manufacturers.

Cost Benefits

- Lower Labor Costs: Automated slitting lines require less manual intervention, reducing labor expenses.

- Efficiency Gains: The speed of slitting operations means that more material can be processed in less time, enhancing overall productivity.

Waste Minimization

- Reduced Scrap: Precision slitting minimizes the amount of scrap generated, which not only saves material costs but also lessens environmental impact.

- Optimized Material Use: By providing custom widths, slitting allows manufacturers to use materials more effectively, further reducing waste.

Quality Assurance in Slitting

Ensuring quality in the slitting process is paramount. Manufacturers must implement rigorous quality control measures to maintain high standards.

Quality Control Processes

- Regular Inspections: Consistent monitoring of the slitting process helps identify any issues before they affect the final product.

- Adherence to Standards: Compliance with industry standards ensures that the finished strips meet all necessary specifications.

Customer Satisfaction

High-quality slitting operations lead to satisfied customers, as precise and reliable products can enhance their own manufacturing processes. This, in turn, fosters long-term relationships between slitting service providers and their clients.

Choosing the Right Slitting Service Provider

Selecting a reliable slitting service provider is crucial for manufacturers seeking quality and efficiency. Several factors should be considered when making this choice.

Expertise and Experience

- Technical Knowledge: A provider with extensive experience in slitting technology will be better equipped to handle various materials and thicknesses.

- Skilled Workforce: A knowledgeable team can ensure that the slitting process runs smoothly and efficiently.

Range of Services

- Diverse Capabilities: A provider that offers a variety of slitting techniques can better cater to the specific needs of different applications.

- Value-Added Services: Look for providers that offer additional services, such as recoiling, cut-to-length, and deburring.

Future Trends in Steel Slitting

As the industry evolves, several trends are shaping the future of steel slitting lines. Staying abreast of these developments is essential for manufacturers looking to maintain a competitive edge.

Increased Automation

The trend toward automation is expected to continue, with more advanced robotics and AI-driven systems being integrated into slitting lines. This will enhance efficiency and precision even further.

Sustainable Practices

With growing awareness of environmental issues, there is a push for more sustainable practices in steel processing. Slitting lines that minimize waste and energy consumption will likely become more prevalent.

Conclusion

Slitting lines are a vital component of precision steel processing, transforming large coils into narrow strips that serve various industries. Their importance cannot be overstated, as they contribute to efficiency, cost savings, and reduced waste. As technology continues to advance, slitting lines will evolve, further enhancing their capabilities and applications. For manufacturers, understanding the role of slitting lines is essential for optimizing their production processes and ensuring the quality of their products.

In the ever-changing landscape of steel processing, slitting lines represent a fusion of engineering excellence and industrial necessity, driving innovation and efficiency in manufacturing.