Emerging Innovations in Steel Coil Slitting for the Metal Processing Industry

In the ever-evolving landscape of the metal processing industry, steel coil slitting has emerged as a fundamental operation, enabling manufacturers to transform large coils of steel into narrower strips suitable for various applications. As technology advances, the innovations in steel coil slitting are not only enhancing productivity but also improving precision, safety, and overall efficiency. This article delves into the latest trends and breakthroughs in this crucial area, exploring how these advancements are reshaping the industry

The Evolution of Steel Coil Slitting Technology

Steel coil slitting has undergone significant transformation over the years, evolving from manual operations to highly automated processes. This evolution can be traced through several key phases:

Historical Context

Initially, steel slitting involved manual labor, where operators used rudimentary tools to cut coils into strips. This method was labor-intensive and prone to errors, leading to inconsistencies in product quality.

Automation and Mechanization

With the advent of technology, mechanical slitting machines began to emerge. These machines automated the cutting process, significantly increasing speed and reducing the risk of human error. However, they still required manual intervention for setup and adjustments.

Digital Transformation

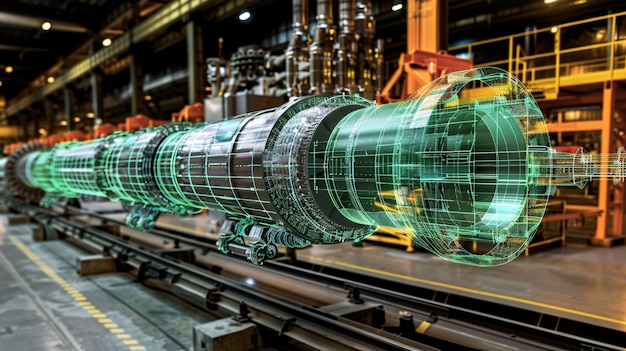

The latest phase in the evolution of steel coil slitting is the integration of digital technologies. Modern machines are equipped with advanced sensors, IoT capabilities, and AI algorithms that not only streamline operations but also provide real-time data analytics for improved decision-making.

Key Innovations in Steel Coil Slitting

The advancements in steel coil slitting technology are characterized by several innovative features that enhance performance and efficiency.

Advanced Automation Systems

Automation is at the forefront of modern steel coil slitting operations. Automated systems streamline the loading and unloading processes, minimizing manual labor and reducing the risk of accidents. Key aspects include:

- Robotic Arms: These devices facilitate the handling of heavy coils, ensuring safe and efficient movement.

- Automated Alignment: Advanced sensors ensure precise alignment of coils before slitting, which reduces waste and improves cut quality.

Precision Cutting Technologies

Precision is paramount in steel coil slitting, and recent innovations have focused on enhancing cutting accuracy. Technologies such as:

- Laser Cutting: This method utilizes high-powered lasers to achieve incredibly clean cuts with minimal burrs, enhancing the quality of the finished product.

- High-Speed Blades: The introduction of specialized blade materials and coatings allows for faster cutting speeds while maintaining sharpness and durability.

Real-Time Monitoring and Control

The integration of real-time monitoring systems has revolutionized steel coil slitting operations. These systems employ:

- IoT Connectivity: Machines can now communicate with each other and with centralized control systems, allowing for remote monitoring and diagnostics.

- Data Analytics: By analyzing performance data, manufacturers can identify inefficiencies and optimize processes, leading to reduced downtime and improved productivity.

Enhancing Safety in Steel Coil Slitting Operations

Safety is a critical concern in steel processing environments. Innovations in steel coil slitting technology are increasingly focused on enhancing safety measures.

Advanced Safety Features

Modern steel slitting machines are equipped with various safety features designed to protect operators and reduce the risk of accidents. These include:

- Emergency Stop Systems: These systems allow operators to quickly halt operations in case of an emergency, minimizing potential injuries.

- Safety Guards: Physical barriers are now standard on machines to prevent accidental contact with moving parts.

Ergonomic Design

The design of steel coil slitting machines has also evolved to prioritize operator comfort and safety. Features such as adjustable operator stations and noise-reducing enclosures help reduce fatigue and improve working conditions.

The Role of Industry 4.0 in Steel Coil Slitting

Industry 4.0 represents the fourth industrial revolution, characterized by the integration of digital technologies into manufacturing processes. In steel coil slitting, this shift is evident through:

Smart Manufacturing

Smart manufacturing involves the use of connected devices and systems that communicate with each other to optimize production. Key components include:

- Predictive Maintenance: By using data analytics, manufacturers can predict when a machine is likely to fail and perform maintenance proactively, reducing downtime.

- Supply Chain Integration: Real-time data sharing across the supply chain enhances inventory management and demand forecasting.

Enhanced Customization

Industry 4.0 technologies enable manufacturers to offer greater customization options. Through advanced software, clients can specify their requirements, and machines can adjust settings automatically to meet these demands.

Environmental Considerations in Steel Coil Slitting

As the manufacturing industry faces increasing pressure to reduce its environmental footprint, innovations in steel coil slitting are also focusing on sustainability.

Energy Efficiency

Modern slitting machines are designed to be more energy-efficient, employing:

- Energy-Saving Technologies: These include variable frequency drives that optimize motor speed and reduce energy consumption.

- Regenerative Braking Systems: These systems recover energy during braking and feed it back into the system, minimizing waste.

Waste Reduction

Innovative cutting techniques and improved precision lead to less scrap material. By optimizing cutting patterns and utilizing advanced software, manufacturers can significantly reduce waste.

The Future of Steel Coil Slitting

The future of steel coil slitting is poised for further advancements, driven by ongoing technological developments and industry demands.

Integration of AI and Machine Learning

Artificial intelligence and machine learning are set to play a significant role in the future of steel coil slitting. These technologies can:

- Optimize Cutting Patterns: AI algorithms can analyze historical data to determine the most efficient cutting patterns, reducing waste and maximizing yield.

- Enhance Quality Control: Machine learning can identify defects in real-time, allowing for immediate adjustments to maintain quality standards.

Continued Focus on Sustainability

As environmental concerns grow, the steel processing industry will likely continue prioritizing sustainable practices. Innovations may include:

- Recycling Initiatives: Enhanced systems for recycling scrap metal generated during slitting processes.

- Carbon Footprint Reduction: Technologies aimed at minimizing greenhouse gas emissions associated with steel production.

Challenges in Implementing Innovations

While the advancements in steel coil slitting technology are promising, manufacturers face several challenges in implementation.

High Initial Investment

The cost of acquiring advanced slitting machines equipped with the latest technologies can be substantial. Smaller manufacturers may struggle to justify these investments.

Skill Gaps

As technology evolves, there is a growing need for skilled operators who can manage and maintain advanced machinery. Manufacturers must invest in training programs to bridge this skills gap.

Conclusion

The innovations in steel coil slitting are reshaping the metal processing industry, driving improvements in efficiency, precision, and safety. As technology continues to advance, manufacturers must adapt to these changes while addressing challenges such as high initial investments and skill gaps. By embracing these innovations, the industry can enhance productivity and sustainability, ensuring a competitive edge in the global market.