Heavy Gauge Steel Slitting: Strategies for Increased Production Efficiency

In the competitive landscape of manufacturing, optimizing production processes is paramount. Heavy gauge steel slitting emerges as a critical strategy for enhancing efficiency and reducing waste. This article delves into various aspects of heavy gauge steel slitting, exploring how it can significantly improve productivity and streamline operations in manufacturing environments

Understanding Heavy Gauge Steel Slitting

Heavy gauge steel slitting is a specialized process that involves cutting large coils of steel into narrower strips. This method is essential for manufacturers that require specific dimensions for their products. The precision and customization offered by slitting services ensure that businesses can meet their production needs without excess material wastage.

The Importance of Precision

Precision in steel slitting is vital for several reasons:

- Cost Efficiency: Accurate cuts minimize waste, reducing overall material costs.

- Quality Control: Consistent dimensions lead to better product quality and fewer defects.

- Production Speed: Quick turnaround times for slitting services can significantly enhance the overall production timeline.

Applications in Various Industries

Heavy gauge steel slitting is utilized across multiple sectors, including:

- Automotive: For manufacturing components that require specific steel grades and dimensions.

- Construction: Providing materials for structural applications.

- Energy: Supplying steel for pipelines and other energy infrastructure.

Streamlining Manufacturing Processes

One of the primary benefits of heavy gauge steel slitting is its ability to streamline manufacturing processes. By providing pre-slit materials, manufacturers can reduce the preparation time needed before production begins.

Reducing Preparation Time

Preparation time can be a bottleneck in manufacturing. By utilizing slitting services, companies can:

- Receive steel that is ready to use upon delivery.

- Eliminate the need for additional cutting or processing.

- Focus on core manufacturing activities rather than material preparation.

Enhancing Workflow Efficiency

When steel arrives in the exact specifications needed, it allows for a more seamless workflow. This leads to:

- Faster production cycles.

- Improved scheduling and resource allocation.

- Better alignment of production goals with actual output.

Waste Reduction Strategies

Waste reduction is a critical concern in manufacturing. Heavy gauge steel slitting not only minimizes excess material but also helps in managing overall production waste.

Minimizing Scrap Material

By providing steel that is tailored to specific requirements, slitting services significantly reduce scrap. This is achieved through:

- Customized cutting that aligns with production needs.

- Efficient material usage that maximizes yield.

Lowering Rejection Rates

With precise dimensions and high-quality materials, manufacturers experience lower rejection rates during production. This improvement can be attributed to:

- Enhanced quality control measures.

- Better-fitting components that reduce assembly issues.

Enhancing Material Handling

Efficient material handling is crucial for maintaining a smooth production process. Heavy gauge steel slitting can improve handling practices in various ways.

Simplifying Logistics

When steel is pre-slit to the required dimensions, logistics become more manageable. This simplification includes:

- Easier transportation of materials due to uniform sizes.

- Reduced labor costs associated with handling larger coils.

Improving Storage Solutions

With pre-slit materials, storage becomes more efficient. Manufacturers can:

- Optimize warehouse space by storing only the necessary dimensions.

- Reduce handling time when retrieving materials for production.

The Role of Technology in Steel Slitting

Advancements in technology have revolutionized heavy gauge steel slitting, making it more efficient and precise.

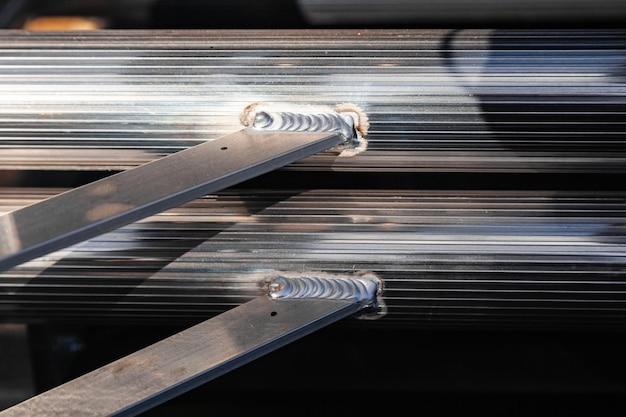

Automated Slitting Machines

Modern slitting machines utilize automation to enhance performance. Benefits include:

- Increased speed and accuracy in cutting.

- Reduced labor requirements, leading to cost savings.

Data-Driven Decision Making

The integration of data analytics in the slitting process allows manufacturers to:

- Monitor production metrics in real time.

- Make informed adjustments to improve efficiency.

Collaborating with Expert Slitting Services

Partnering with experienced steel slitting service providers can yield significant advantages for manufacturers.

Access to Expertise

Expert slitting services bring a wealth of knowledge and experience, enabling manufacturers to:

- Identify the best steel grades for their applications.

- Utilize advanced techniques that enhance production efficiency.

Customized Solutions

Every manufacturing operation is unique. Reliable slitting services offer:

- Tailored solutions that address specific production challenges.

- Flexibility in order quantities and delivery schedules.

Case Studies: Success Stories in Steel Slitting

Examining real-world applications of heavy gauge steel slitting can provide valuable insights into its effectiveness.

Automotive Industry Example

A leading automotive manufacturer implemented heavy gauge steel slitting to enhance their production line. The results included:

- A 30% reduction in material waste.

- Improved production speeds, leading to faster vehicle assembly.

Construction Sector Application

In the construction industry, a major contractor utilized slitting services to provide materials for structural components. The outcomes included:

- Streamlined supply chains that reduced delays.

- Enhanced quality of materials leading to fewer onsite issues.

Future Trends in Steel Slitting

As industries evolve, so do the methods and technologies used in steel slitting. Emerging trends to watch include:

Sustainable Practices

With a growing emphasis on sustainability, steel slitting services are adapting by:

- Implementing eco-friendly practices that reduce environmental impact.

- Offering recycled steel options to meet demand for sustainable materials.

Advanced Materials

The development of new steel grades and composites will likely influence slitting practices. Manufacturers can expect:

- Innovations that improve performance and versatility.

- Greater customization options to meet diverse industry needs.

Conclusion

Heavy gauge steel slitting presents a multitude of benefits for manufacturing efficiency, waste reduction, and overall productivity. By investing in high-quality slitting services and leveraging modern technologies, businesses can position themselves for success in an increasingly competitive market. As industries continue to evolve, the importance of effective steel slitting strategies will only grow, making it a critical component of any successful manufacturing operation.

This article provides a comprehensive overview of heavy gauge steel slitting, emphasizing its strategic advantages for increasing production efficiency. Each section is designed to engage readers while delivering valuable insights into the process and its applications. The use of markdown formatting enhances readability, making it easier for readers to navigate through the content.