Heavy Gauge Steel Reconditioning

Our capabilities are to go far beyond just processing heavy gauge steel products. We are also able to apply our expertise in steel coil reconditioning to materials that may otherwise be considered useless. Please take a look below at the strategies we employ to help bring new life to your steel material.

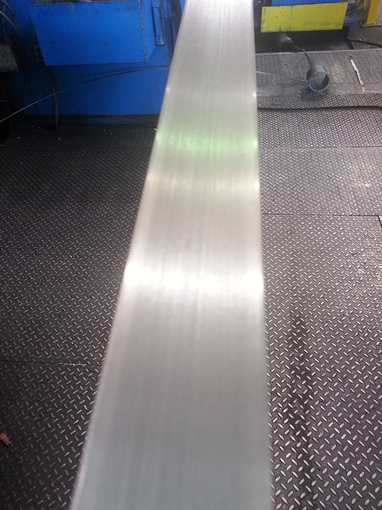

Brushing

The MD Metal’s brush-bright system processes material through a series of brushes and pads to remove unwanted substances on the surface of the steel. This system can help remove light rust or stain, excess oil, lube, and other surface imperfections, rendering your material much more attractive and fit for commercial applications.

Decambering

Camber refers to the horizontal bend or wave on a strip of metal that occasionally results from the slitting process. Our Tishken edging lines have a sequence of decambering units as well as edging that we can use on narrow material to remove any camber induced by faulty slitting.

Re-slitting

Our precision narrow slitting lines have the capability to re-slit already slit narrow coils that may have been slit to the incorrect size or are obsolete. We have the capability to re-slit steel coils as narrow as 1.5”.

Gauge Reduction

We have the ability to reduce the gauge of narrow coils. Degree of reduction is determined by the width and grade of the material.

Bad Burr and Edges

MD Metals can repair material up to .375″ thick and 6″ wide. We can generally correct material up to .250” thick and up to 5” wide, leaving you with an attractive finished edged product that’s fit for all kinds of industrial applications.

Before Rust Removal

After Rust Removal